No products

Prices are tax included Prices are tax excluded

Sanding

Once you're done with the lamination and the hot-coating steps of the process, you will need to sand the board to give a perfectly smooth finish.

- D.I.Y. Solutions

- Shaping

- Glass

- Sanding

- Fins and fins boxes

- Déco

- Accesoires

- Eco-friendly

Filters

-

Abrasives

A complete range of abrasives, in velcro disks and in sheets format, to allow you to perfect your sanding.

From the grain 80 which you will use to rough-hew, or sand boxes, to the finest grains of wet sanding papers, you will necessarily find in this category all abrasives you may need.

-

Sanding pads

Choose the diameter and the foam density of your sanding pad according to the use.

We generally proceed with a big hard pad (8 " - 200mm) on the plane surfaces of the board, and with a small soft pad (6 " - 150mm) for a more precise work on the curved zones or the rails, the softer density of the foam adapting itself to the roundings and avoiding any deformation of your initial shape. -

Sanding machines

Sanding process will require the use of a rotating sanding machine hand-held with disks (ranging from 600 to 2000 rpm).

The Milwaukee AP12QE sander is perfect for these duties, widely used in the professional surfboard making workshops around the World. Close to 1kg lighter than any of its competitors, it is the perfect tool combine comfort of use and precision work.

-

Polish and lustring

With your sanding machine, featuring a polishing plate in genuine sheep skin, and some polish, keep working on the board, in circular movements, until you reach the desired outcome. Use a moderate speed of rotation of the sander, in order to avoid any over-heating. Finally, protect your work with a finish liquid, and a synthetic lustring disk, with a tolerance to higher rpm.

These additional steps will guarantee the best mirror effect you can obtain !

-

Security products

Most of the materials used for the manufacturing of a surfboard are unfortunately toxic and corrosive.

Do not neglect how toxic the can be and protect yourselves ! Safety first !

-

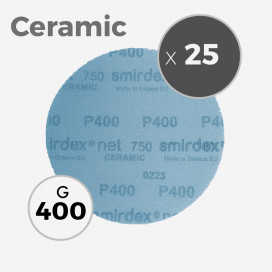

25 Smirdex net 750 ceramic abrasive discs diameter 150mm - grit 400

Smirdex net 750 ceramic abrasive disc diameter 150mm - grit 400, sold by 25 units.

18,00 € In Stock -

150mm Merino Lambs Wool Velcro Bonnet with 32mm Wool Pile

Ultimate pure natural sheepskin velcro backed.

9,90 € In Stock -

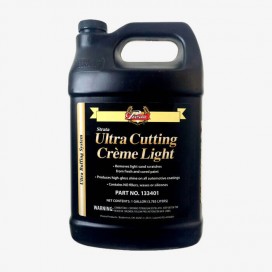

Ultra Cutting Creme Light - 3.78L

Ultra Cutting Crème Light is a medium abrasive polish designed to lift P2000 sandpaper as well as fine to medium scratches on all types of varnish and direct gloss, fresh or old paintwork.

117,00 € In Stock -

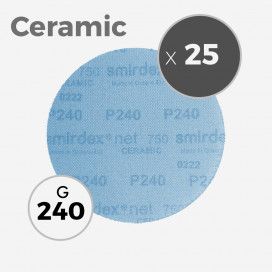

25 Smirdex net 750 ceramic abrasive discs diameter 150mm - grit 240

Smirdex net 750 ceramic abrasive disc diameter 150mm - grit 240, sold by 25 units.

18,00 € In Stock -

6" (150MM) SUPER HARD DENSITY SANDING PAD

6" (150mm) sanding pad with Velcro or vinyl interface - density Super Hard. Thread M14 (european metric). Thread 5/8" (US metric) to order.

35,00 € In Stock -

8" (200MM) SUPER HARD DENSITY SANDING PAD : Fixing method - vinyl,...

8" (200mm) sanding pad - density Super Hard. Thread M14 (european metric). Thread 5/8" (US metric) to order.

42,00 € In Stock -

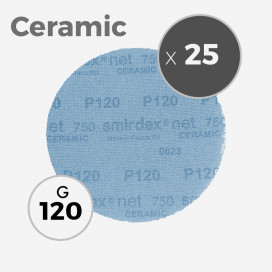

25 Smirdex net 750 ceramic abrasive discs diameter 150mm - grit 120

Smirdex net 750 ceramic abrasive disc diameter 150mm - grit 120, sold by 25 units.

18,00 € In Stock -

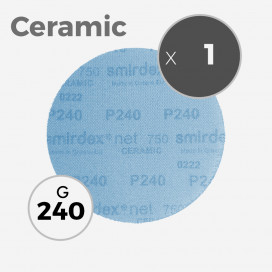

Smirdex net 750 ceramic abrasive disc diameter 150mm - grit 240

Smirdex net 750 ceramic abrasive disc diameter 150mm - grit 240, sold by unit.

1,00 € In Stock -

Boite de 50 disques abrasifs Abranet diamètre 150mm - grain 600, MIRKA

Disque abrasif Abranet Mirka diamètre 150mm - grain 600, vendu par 50 disques.

51,60 € In Stock -

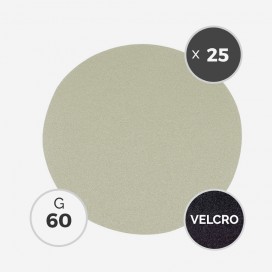

60 grit 205mm sanding disc (25 discs), 3M

3M White Line sanding disc - grit 120 (25 discs). Velcro self adhesive - 205 mm diameter.

30,60 € In Stock -

Abrasif sur mousse en feuille de 115 x 125mm - grain 1000 - ponçage...

Abrasif sur mousse en feuille de 115 x 125mm - grain 1000 - ponçage à l'eau?, vendu à l'unité.

0,30 € In Stock -

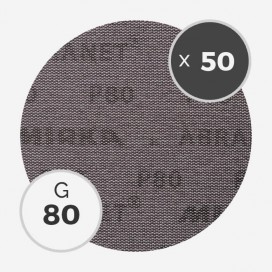

Boite de 50 disques abrasifs Abranet diamètre 150mm - grain 80, MIRKA

Disque abrasif Abranet Mirka diamètre 150mm - grain 80, vendu par 50 disques.

57,90 € In Stock -

25 disques abrasifs Abranet diamètre 150mm - grain 120, MIRKA

Disque abrasif Abranet Mirka diamètre 150mm - grain 120, vendu par 25 disques.

28,50 € In Stock -

Boite de 50 disques abrasifs Abranet diamètre 200mm - grain 400, MIRKA

Disque abrasif Abranet Mirka diamètre 200mm - grain 400, vendu par 50 disques.

83,20 € In Stock -

25 disques abrasifs Abranet diamètre 200mm - grain 240, MIRKA

Disque abrasif Abranet Mirka diamètre 200mm - grain 120, vendu par 25 disques.

45,70 € In Stock -

Abrasif sur mousse en feuille de 115 x 125mm - grain 240 - ponçage...

Abrasif sur mousse en feuille de 115 x 125mm - grain 240 - ponçage à sec?, vendu à l'unité.

0,25 € In Stock -

Boite de 50 disques abrasifs Abranet diamètre 200mm - grain 240, MIRKA

Disque abrasif Abranet Mirka diamètre 200mm - grain 240, vendu par 50 disques.

83,20 € In Stock -

Boite de 50 disques abrasifs Abranet diamètre 200mm - grain 80, MIRKA

Disque abrasif Abranet Mirka diamètre 200mm - grain 80, vendu par 50 disques.

98,20 € In Stock -

25 disques abrasifs Abranet diamètre 200mm - grain 80, MIRKA

Disque abrasif Abranet Mirka diamètre 200mm - grain 80, vendu par 25 disques.

54,30 € In Stock -

Abrasif sur mousse en feuille de 115 x 125mm - grain 180 - ponçage...

Abrasif sur mousse en feuille de 115 x 125mm - grain 180 - ponçage à sec?, vendu à l'unité.

0,25 € In Stock -

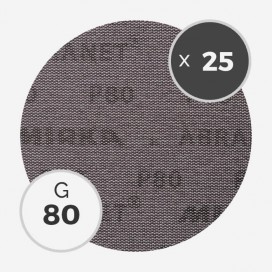

25 disques abrasifs Abranet diamètre 150mm - grain 80, MIRKA

Disque abrasif Abranet Mirka diamètre 150mm - grain 80, vendu par 25 disques.

32,10 € In Stock -

180 grit 205mm sanding disc (50 discs), 3M

3M White Line sanding disc - grit 180 (50 discs). Velcro self adhesive - 205 mm diameter.

41,10 € In Stock -

Disposable Protective Coverall Safety Work Wear

G-PRO STANDARD T5/6 EN1149 TXL WETSUIT SMS WHITE Coverall in white antistatic SMS polypropylene. Low linting. Material that effectively wicks away perspiration. Elasticated 3-panel hood, 2-way zipper with adhesive flap. Elasticated waist, wrists and ankles. CE Category 3 EN13034, EN13982, EN1149, EN 1073

6,40 € In Stock -

6 Inch Extra Hard Flexpad velcro 14mm Hub

The EXTRA HARD density purple and white Velcro FLEXPAD sanding pad is the brand's most rigid pad. Perfect for laying flat after a hot coat It has a 14mm female attachment, and therefore adapts directly to European sanders. The sanding face is coated with a rigid fabric, velcro type, to which you will attach your sanding paper. Maximum recommended...

40,00 € In Stock -

-

120 grit 205mm sanding disc (1 DISC), 3M

3M White Line sanding disc - grit 120 (1 disc). Velcro self adhesive - 205 mm diameter.

1,10 € In Stock -

6" (150MM) Soft density Sanding Pad, VIRAL Surf

6" (150mm) sanding pad with Velcro interface - density Soft. Thread M14 (european metric). Thread 5/8" (US metric) to order.

35,00 € In Stock -

2 3/4" (70MM) HARD DENSITY SANDING PAD

2 3/4" (70mm) sanding pad - density Hard. Specially conceived for sanding laps and glass-on fins. Thread M14 (european metric). Thread 5/8" (US metric) to order. Our back up pads are custom made for surfboard manufacturing.

19,90 € In Stock